Description

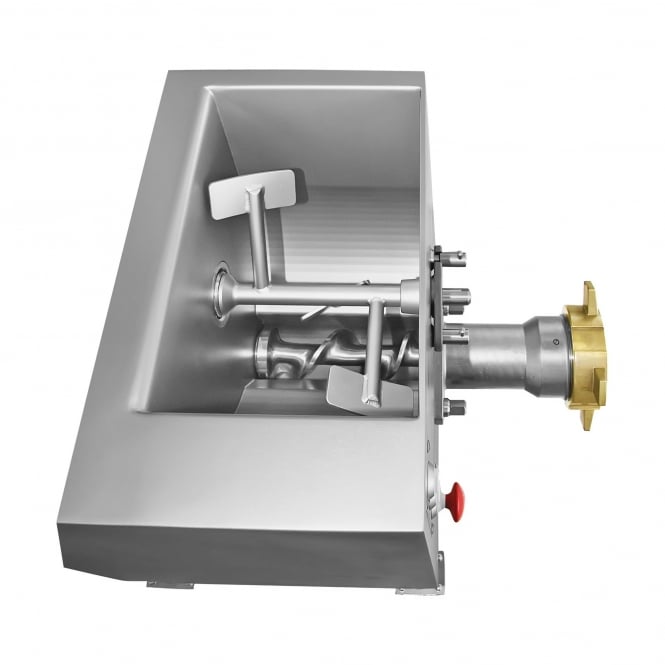

The Kolbe MW52-120 mixer grinder is what we believe to be the ultimate in mincer grinders, with a massive 240lb hopper capacity, a 52 size head and a throughput of 1700kg/h in optimal conditions the MW52-120 is ideal for use in medium to large meat processors and supermarkets.

The MW52-120 mixer grinder comes with the option to add an outlet protection guard for mincing through plates with holes greater than 8mm. The mixer grinder is constructed from high quality stainless steel and is often to referred to as the ‘German Tank’ due to its weight and physical appearance.

The MW52-120 mixer grinder has been constructed to Kolbe’s usual high standards and finish and due to the precision geometry of the worm and head it ensures the best possible homogeneity particularly when mixing with herbs and spices etc.

The mixer grinder comes as standard with a L&W knife and 4.5mm plate, other sizes are available to buy from the website or direct from our spares department on the phone should you require them. The mixer grinders high torque level provides an extremely clean cut appearance.

The main drive motor and mixing motor are separated from the hopper by using a double seal system with a gap between each seal. This ensures that even if something should get passed the first seal it falls into the gap between the seals before it get through to the motors themselves. This gap is easily flushed out using a hose pipe, this is placed in the inlet hole on the side of the machine and the water flushes through the gap This is a very important feature to have in a mixer grinder and prevents any product making its way into the motor and gearbox and contaminating them.

The MW52-120 also comes as standard with the ‘auto-reverse system’ which helps prevent unmixed product being left in the worm. This system changes the direction of the mixing paddle in the machine every 20-30 seconds and spins the worm backwards for approx 2 secs to force any product lying in the worm back into the chamber. This feature of the mixer grinder almost eliminates the need for putting that first few pounds back in the hopper.

Please take a look at the rest of the Kolbe range of mixer grinders should this machine not be correct for your production requirements. They start with the MWK32-45 and MWK32-80 mixer grinders and move up to the AWM52-240 and AWM56-240 mixer grinders.

Reviews

There are no reviews yet.